Innomed Orthopedic Instruments

Menu

Selected:

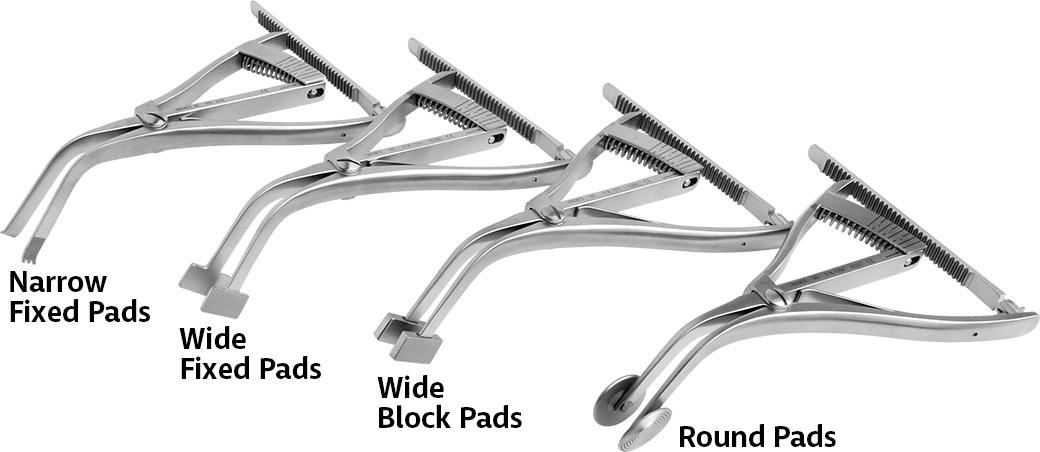

Scott Femoral Tibial Tensor/Spreader…

Scott Femoral Tibial Tensor/Spreader – Narrow Fixed Pads

Richard Scott, MD

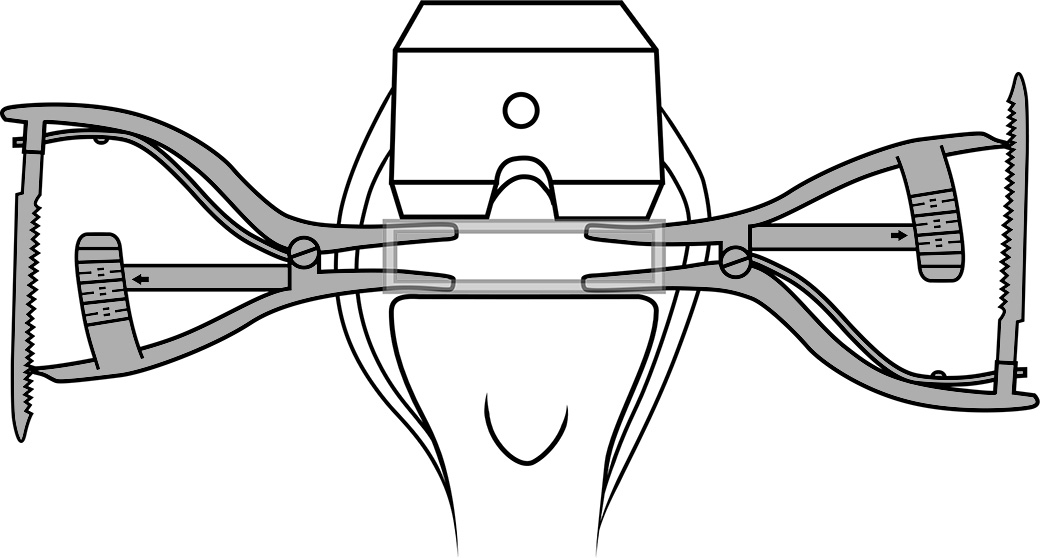

Used before determining femoral component rotation to help properly tense the medial and lateral ligaments and help assure a stable, balanced flexion gap

An important part of surgical technique during total knee arthroplasty is the establishment of a symmetric balanced flexion gap. This can be achieved by tensing the medial and lateral ligaments with laminar spreaders and rotating the femoral component until a rectangular space is formed. The calibrated Tensor/Spreader allows the surgeon to choose a reproducible amount of tension across the medial or lateral flexion space.

In the varus knee, any medial release necessary to balance the knee in extension is performed first. In the valgus knee, the flexion gap can be balanced before the extension gap if the lateral retinaculum (not the lateral collateral ligament) is all that needs releasing to correct the deformity.

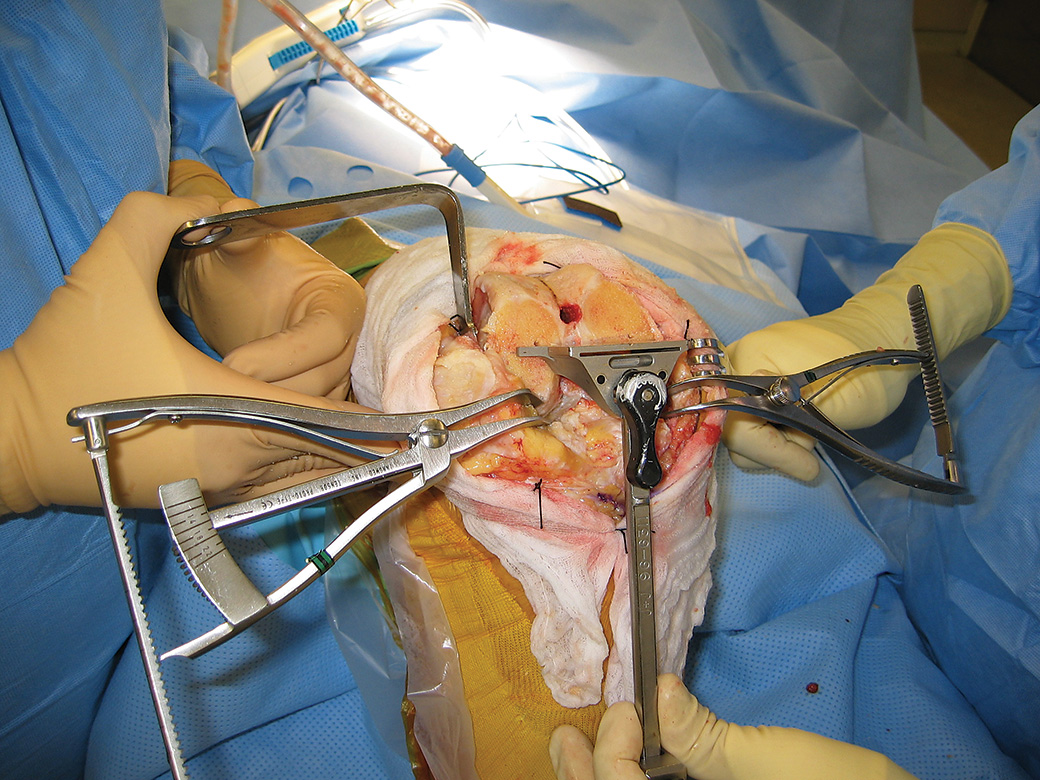

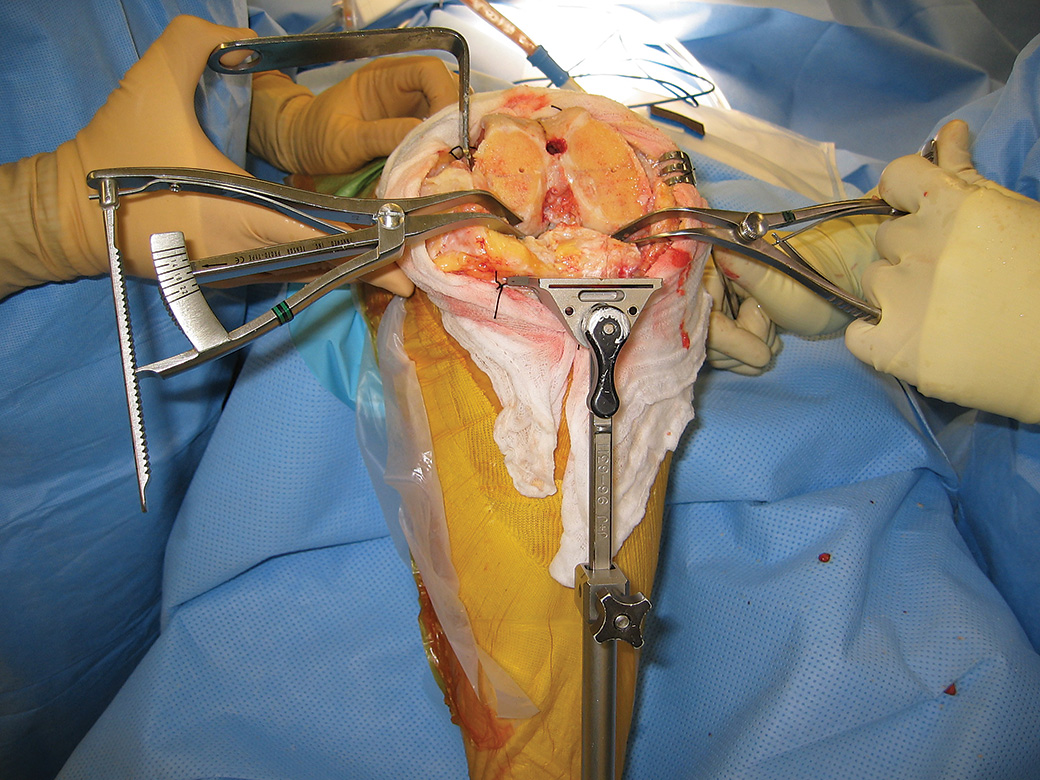

The spreader can be used before or after tibial preparation and also during revision surgery after a well-aligned tibial platform has been established.

The knee is flexed 90 degrees. Any medial retractor is removed. The medial gap is tensed with a plain or calibrated laminar spreader that is opened until the medial collateral ligament is fully tensed. The Tensor/Spreader is applied laterally and opened to the desired tension on the indicator. The femoral component is rotated until a rectangular gap is formed based off the tibial cut or an external tibial alignment device (if the tibial resection has not yet been performed).

Product Number(s)

1995

Dimensions

Overall Length: 7″ (17,8 cm)

Blade Width: 7 mm

Opens to: 40 mm

Accuracy Statement for devices with a measuring function: Devices with a measuring function are considered non-critical, non-calibrated, and are intended for reference-only measurements. While it provides a helpful visual guide for relative measurements, it is not calibrated to specific precision standards. Measurements taken with this device should not be considered accurate enough for critical applications requiring strict dimensional tolerances. General manufacturing tolerances of +\- 1% at each graduation, or 2% of the full scale apply, but no conformance qualifications are provided or implied.